MWE

Features:

- A safe, quick and simple way to clamp Dies, Workpieces and Fixtures

- Easily inserted into existing T-Slots. Easily positioned without any set-up

- Manually operated. No hydraulic or pneumatic components necessary

- Clamping force is obtained through the patented OPTIMA Toggle System. Full pressure is achieved quickly and easily by turning the low torque "activation nut" 1800

- Self-locking in clamped position

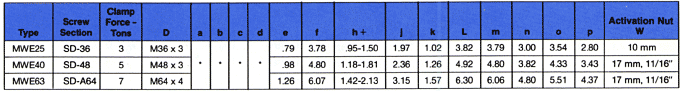

Technical Data

Operating Procedure (SD):

To Clamp

- Visually inspect clamp for obvious defects and make sure that the arrow on top of the "activation-nut" is pointing toward the RED dot.

- Place clamp into T-slot.

- Unscrew clamping screw sufficiently so that clamp jaw easily passes over the die shoe.

- Push clamp forward (toward die) as far as possible to ensure proper seating. Make certain that the die shoe surface is free of debris and lubric·ants.

- Pre-clamp by hand tightening the clamping screw as far as possible (to pre-torque value) so that solid contact with the die surface has been achieved. Make certain that the unit is not cocked. Tapping the frame of the unit (with fist) while hand-tightening will ensure proper fit.

Note: Maximum clamping force can be achieved by pre-clamping with a spanner wrench rather than hand-tig hten i ng. - With the use of a hex head wrench turn the "activation nut" 1800 until it reaches its stop and the arrow is pointing toward the GREEN dot.

To Unclamp - Reverse procedure.

Operating Procedure (SD-A):

To Clamp

Due to an internal clutch mechanism preclamping and clamping are both activated by the activation nut. The activation nut is turned with a socket or open end wrench until the indicator line is pointing toward the green dot.

To Unclamp - Reverse procedure

Ordering Information

When ordering or requesting a quote, please take a few minutes to complete the following data sheet.

Necessary Data

Range of die shoe thickness: ________ min. ________ max.

(min. and max. values must be with in .25" of each other)

Press tonnage: ________

Weight of dies: ________ top ________ bottom

Clearance between ram and bolster (shut height): ___________

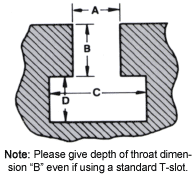

T-Slot Dimensions

If standard: ________

If non-standard:

Width of throat (A) _______

Depth of throat (B) _______

Width of head (C) _______

Depth of head (D) _______