OHZ-K

Hydro-Mechanical Clamping Unit

Area of application

The hydro-mechanical clamp unit type OHZ-K is designed for machine dies and special machines of various types. It is particularly suitable for clamping carriages, pallets, turn-tables and similar objects. It is rigidly installed at various points, for example, on tailstocks, machine frames or gantries. Its use requires flat clamping surfaces.

Due to the low installation cost, the hydro-mechanical clamp unit is suitable both for initial installations and retro-fits.

Mode of operation

A hydraulically actuated mechanically locking toggle mechanism transmits its clamping force to a tie rod that clamps the die in the tool surface.

The clamping force is applied in a purely mechanical manner whereby the toggle mechanism is moved to the clamping point by means of hydraulic pressure. The clamp unit, together with the tie rod, produces a tension effect. Due to the tension thus produced, the die is clamped between the tie rod head and the clamping surface, and at the same time is mechanically locked in place.

Application of the clamping force by:

- Tension movement of the clamp unit

Distinguishing features

The clamp unit is fitted with the well-proven Optima toggle mechanism. In this system, the clamping force required is transmitted by mechanical components which are actuated, with low hydraulic pressure, only during the clamping or release process. The clamping force is thus independent of the compressibility of the pressure medium, operating temperatures and line losses.

Due to the patented Optima-"Aktivator", the clamping force is continuously and directly monitored. For this to function there must not be any hydraulic pressure on the clamp unit. In this control system, the clamp units are connected to the machine control system via electrical switches (precision limit switches). In the event of failure of the clamping force, snapping of the tie rod, or plastic deformations at the clamping point, an electrical signal is produced and passed to the machine control system. Irregularities of this kind result in the machine being stopped.

This control system ensures the highest degree of safety.

When using multiple clamping surfaces, maximum thickness tolerances of ±0.2 mm are permitted.

Electrical control of the following functions (switches):

- Continuous monitoring of clamping force (S6)

Advantages

- Mechanical self-locking

- Limited space required due to compact dimension

- Maximum safety due to continuous monitoring of clamping force by the "Aktivator"

- Central control

- Hydraulic pressure only necessary during the clamping or release process

- High mechanical load capacity

Construction

The individual components of the toggle mechanism are made from various hardened steels.

The clamp unit is secured by four bolts of strength class 10.9 (supplied). The thread dimension depends on the type (see technical drawing).

Technical data

| Type | OHZ-K 50 S | OHZ-K 100 S | OHZ-K 200 S | |

| Nominal clamping force | kN | 50 | 100 | 200 |

| Set pressure | bar | 70 | 90 | 90 |

| Max. load capacity | kN | 63 | 125 | 250 |

| Max. operating pressure (min. set pressure + 20 bar) | bar | 100 | 140 | 140 |

| Release stroke | mm (ca.) | 2 | 4.5 | 4.5 |

| Die thickness tolerance | mm | ± 0.2 | ± 0.2 | ± 0.2 |

| Oil volume required (each process) clamping | cm3 | ca. 30 | ca. 70 | ca. 130 |

| Oil volume required (each process) release | cm3 | ca. 30 | ca. 70 | ca. 130 |

| Delivery rate per unit* | l/min. | 0.4-0.6 | 1.0-1.5 | 1.5-2.0 |

| Weight | kg (ca.) | 10 | 15 | 20 |

| Hydraulic connections | G¼ | G¼ | G¼ | |

| Max. operating temperature | °C | 70 | 70 | 70 |

| Pressure medium | Hydraulic oil ISO Standard 3448 ISO VCE (DIN 51519) |

|||

| Viscosity | 25 - 60 cST/40°C | |||

| Filter | 20 - 25 µm | |||

*If a pump with a higher delivery rate than necessary is used, the oil flow must be reduced

by means of flow regulating valves or oneway restrictors.

Monitoring of clamping force

| OHZ-K 50 S | |

| Inductive proximity switch | |

| Switching function: | p-n-p normally open end |

| Supply voltage: | 10-30 V DC |

| Switching capability: | 200 mA |

| OHZ-K 100 S OHZ-K 200 S |

|

| Precision switch | |

| Switching function: | single pole change-over snap-action contact |

| Supply voltage: | 250 V AC |

| Switching capability: | 2A/230 V AC 5A/24 V DC |

| Contacts: | screw connection |

| Cable lead-in: | armoured cable 9 |

| Connection cable: | 3m long |

For a water- and oil-tight installation, we

recommend cable screw joints, in conjunction

with a protective sleeve.

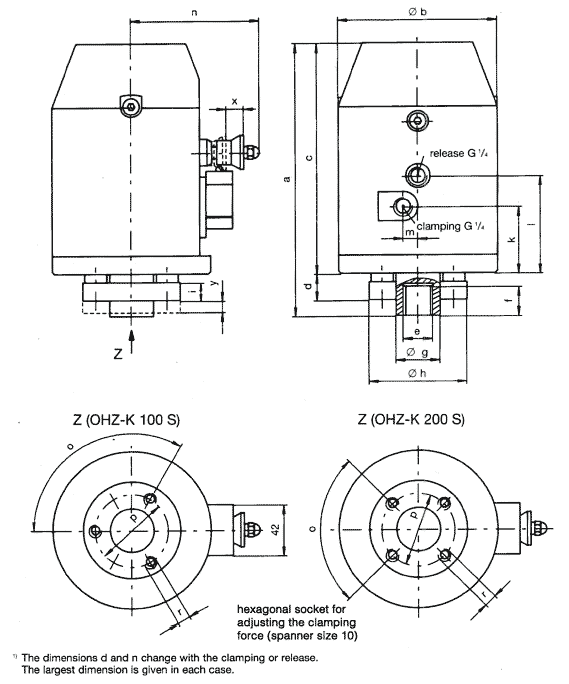

| Type | a | b | c | d1) | e | f | g | h | i | k | l | m | n | o | p | r | s | y ca. |

Weight [kg] |

| OHZ-K 50 S | 190 | 110 | 145 | 21.5 | M 18x1.5 | 22 | 26 | 70 | 12 | 51 | 8.5 | 43.2 | 38 | 3x120° | 60 | M6 | 18 | 2 | 10 |

| Type | a | b | c | d1) | e | f | g | h | i | k | l | m | n | o | p | r | s | y ca. |

Weight [kg] |

| OHZ-K 100 S | 225 | 130 | 190 | 28 | M24x1.5 | 42 | 35.5 | 80 | 15 | 55 | 80 | 12 | 112 | 3x120° | 60 | M8 | 14 | 4.5 | 15 |

| OHZ-K 100 S | 262 | 155 | 226 | 30 | M36x3 | 55 | 50 | 100 | 15 | 76 | 125 | 20 | 114 | 4x90° | 78 | M10 | 14 | 4.5 | 20 |