HEE - Hydraulic C-Frame Clamp

Features:

- A safe, quick and simple way to clamp Dies, Workpieces and Fixtures

- Easily inserted into existing T -Slots, adapts to any Die width

- Allows semi-automated Ole change operations

- Hydraulic activation asures quick and effortless clamping

- Generous piston stroke allows for variations In Die shoe thickness

- Compact design asures minimal space requirement

Technical Data

Operating Procedure (HEE):

To Clamp

- Visually inspect clamp for obvious defects and make certain that the hydraulic power supply is disactivated and the clamp piston is in its fully retracted position.

- Place clamp into T-slot.

- Push clamp forward (toward die) as far as possible to ensure proper seating. Make certain that the die shoe surface is free of debris and lubricants.

- Inspect the gap between the clamping cylinder and die surface to ensure that it does not exceed the stroke "s" of the clamp. Warning: Clamp will not generate clamp force if gap exceeds the stroke "s".

- Activate hydraulic supply.

To Unclamp - Reverse procedure.

Ordering Information

When ordering or requesting a quote, please take a few minutes to complete the following data sheet.

Necessary Data

Range of die shoe thickness: ________ min. ________ max.

(min. and max. values must be with in .25" of each other)

Press tonnage: ________

Weight of dies: ________ top ________ bottom

Clearance between ram and bolster (shut height): ___________

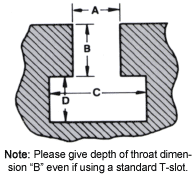

T-Slot Dimensions

If standard: ________

If non-standard:

Width of throat (A) _______

Depth of throat (B) _______

Width of head (C) _______

Depth of head (D) _______