HSD

Hydraulic Clamp Arbour

Area of application

The hydraulic automatic clamp cylinder, type HSD, is designed for medium- and large-sized machines exerting a force of up to about 1,200 tons. It is mainly used for bottom die clamping (with and without clamping edge). In this case lock plates are required on dies which are to clamped.

The clamp cylinder is fitted in recesses in the press bed (or press ram) where it is fixed.

The clamp cylinder places little demand on the periphery of the machine. Its control can be easily combines in the existing machine control system.

Mode of operation

A double-acting hydraulic cylinder, hydraulically controlled, actuates the clamping process. In so doing, the arbour is driven out from the housing of the clamping element until it reaches the clamping position. The arbour is then forced to expand through the push movement of the piston in order to finally apply the clamping force via a tension incline. This method of operation enables all three following movement sequences to be carried out via the push movement of the clamping cylinder.

The release process is carried out by reversing the hydraulic valve. After the arbour is released, it contracts in order to finally retract into the housing of the clamp unit.

Movement sequence for applying the clamping force:

- Driving out the arbour

- Expansion of the arbour

- Clamping stroke of the arbour (release of the clamp cylinder in reverse order)

Distinguishing features

The hydraulically operated clamping cylinder directly produces the necessary clamping force. In so doing, the hydraulic pressure must be maintained throughout the clamping process (optional equipment with non-return valves and pressure switches recommended).

By installing the cylinder in recesses provided for it in the press bed/ram, the surface of the clamping cylinder lies flush with the surface of the press bed or the ram. In addition, the arbour is withdrawn to the idle position below the surface of the ram or bed, thus avoiding any difficulty in changing the dies.

Electrical control of the following functions (switches):

- Arbour released (S1)

- Arbour expanded (S2)

- Pressure control by means of pressure switch on the hydraulic unit advisable.

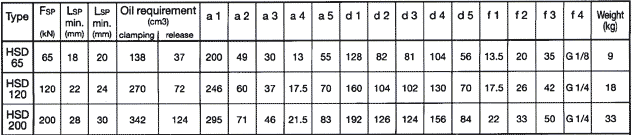

Technical data

| Switch: | 2 inductive proximity switch; p-n-p contact |

| Supply voltage: | 10-30 V DC |

| Cable length: | ca. 3 m |

The automatic clamp cylinder type HSD can be used for operating temperatures of up to 70°C, and a maximum operating pressure of 220 bar.

Advantages

- Fully automatic, and also purely hydraulic operation

- Large clamping thickness tolerance

- Low installation cost

- Central control

- High safety standard due to electric control

- Low maintenance

- Superior corrosion protection

- High clamping force despite compact dimensions of clamping elements

Construction

The clamping element has a gunmetal-finish housing and a gunmetal-finish arbour.

It is secured by four bolts, of strength class 10.9 according to DIN 912 (not included). The thread dimension depends on the type (see technical drawing).